A few weeks ago we had a practice night at our local track, Buddyboys R/C. When I wheeled my car around the track it didn’t seem as smooth, or as quiet as it had in the past. It sat all summer while outdoor season was going on. I hadn’t touched the car in months. I ended up toasting my motor, probably due to running a high C-rating lipo instead of the normal 1100mah Nimh battery (just playing around). It got so hot that it melted the solder on the brushes!

Anyways, a fellow Soup writer, Jim, let me wheel his vehicle around the track for a few laps.. wow what a difference. He’d just gone thru it and did maintenance, and it was clear… my car was due as well. Compared to mine, his car felt like it was BUTTER. Mine felt crunchy and loud..

So I sat down and dug into the car. It’s got probably 20 races on it from last year without really going through a complete tear down. Here’s how it sat. It’s a Losi Mini Late Model BND, converted to EDM class with a Kipps body.

You would think that your car wouldn’t get dirty running on carpet.. but boy would you be wrong! A combination of the soft rubber tires, and the harsh carpet fabric makes the tires shed rubber dust. On top of that you have varying degrees of carpet lint you pick up along the track. Here’s a couple shots of the amount of dust/dirt/rubber that’s picked up.

The main thing I set out to do was clean & lube all of the bearings including the transmission ones to get the car rolling smoother. I broke out my trusty bearing cleaning tools. These include Cow Moo-tor Cleaner & Degreaser and COW Moo-Slick, as well as an RPM Bearing Blaster. Together they are a powerful bearing cleaning arsenal.

MOO-tor Cleaner and Degreaser NO. 789 is a very low flash point, fast evaporating cleaner and degreaser that is ideal for cleaning all your rc parts. Effectively removes grease, oil, soil, and other contaminates. Will not weaken electrical insulations, contacts, relays, and circuit boards. It prevents corrosion and electrical malfunctions caused by water penetration, humidity, condensation by displacing moisture. Plastic, Fabric, Paint, and metal safe. Will not cause premature aging, or drying of components, leaves no residue or films.

MOO-Slick NO. 077 is a fast drying silicone based application that is unaffected by water or oils, heat stable to 400+ degrees, will not; freeze, melt, throw or, collect dust. Fabric, plastic, metal, and paint safe. Replace all your current R/C lubricants that are not dependent on oil weight (IE: Differentials) and get the job done better. Repels corrosion, rust, and pitting of metals. Stops sticking, premature aging, and drying of plastics. Eliminates squeaking, squealing, and other friction related noises. Will not leave any greasy or oily films.

As you can see above, I also use an old toothbrush while cleaning the car. It helps get dirt out of hard to reach places (kinda like it’s purpose in your mouth).

I removed all the bearings from the vehicle (both front wheels, rear hub carriers, and all the bearings in the transmission). I then dropped them into an old Cool Whip container to keep them separate (not all are shown). I used this dish to catch all of the spray from the cleaner and lubricant. I don’t have a utility sink or anything like that, so this is just easier.

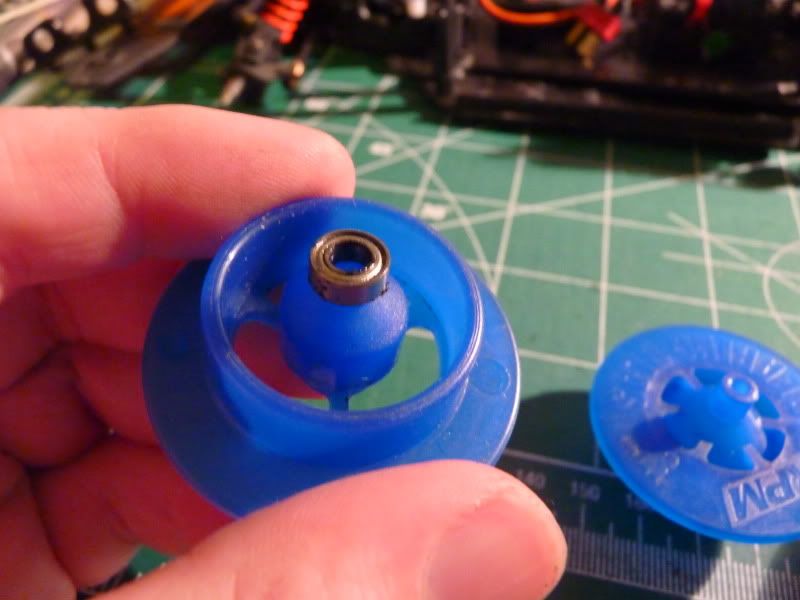

The RPM Bearing Blaster is a indispensable little tool. I bought mine almost 10 years ago. They still make them and run around $10. Basically what it does is blast away debris from your bearings and extend bearing life.

This simple, two piece tool, works with your favorite cleaning agent that is pressurized and has a directional spray tube, in this case, Cow Moo-tor Cleaner & Moo-Slick. The RPM Bearing Blaster has an open, flow through design that eliminates back-pressure problems which also permits more efficient elimination of dirt and grit from the bearings being cleaned. Using hand pressure, you will know for sure the cleaning agent is passing through the bearing and not around it.

The Bearing Blaster works with all bearings with a minimum I.D. of 1/8″ (3mm.) and a maximum O.D. of 3/4″ (19mm.). I’ve found metal shielded bearings clean easiest as you do not have to deal with teflon or rubber shields.

Just place a dirty bearing on the spindle and put the top on. I didn’t use gloves when doing this, but it’s probably a good idea. Just sayin’..

Once assembled like above, simply take your Moo-tor Cleaner (or other degreaser, but the Cow products work AWESOME), and insert the spray tube into the hole of the Bearing Blaster. I give the bearings a few quick squirts, allow it to work in for a second and then follow up with a couple more squirts. You will likely see dirt and grime flow out the bottom of the Bearing Blaster immediately. The design of the Blaster funnels the spray into, and through the bearing to thoroughly clean it.

After the bearing has been cleaned, I followed the Moo-tor spray up with a generous few squirts of the Moo-Slick silicone lubricant. This relubricates the bearing so that it will once again operate smoothly. I did this one bearing at a time, cleaning, then lubricating without removing the bearing from the RPM Bearing Blaster. Once lubed, I carefully removed the cleaned bearing (don’t drop it in the nasty Cool Whip container!), and placed it on a clean paper towel. Wipe the bearing a little bit removing any surface grit left behind. If you wanted to be more thorough, you could do the paper towel trick between degreasing and lubing, but I was pressed for time, and don’t believe my results were negatively affected.

As you can see below… this process DOES work. Look at all that dirt! That was all inside or on the bearings!

After doing the bearing cleaning, I got my car back on the track this past week and it made a world of difference. I actually TQ’d and got a pretty close 2nd place finish in the A-main. Car was a lot quieter (with the help of some Tamiya Ceramic grease in the transmission during reassembly), and felt much smoother overall. Cleaned & lubed bearings are an r/c maintenance must! My car was overdue.

November 1st, 2011

November 1st, 2011  Kevin

Kevin  Posted in

Posted in  Tags:

Tags: