On my Axial Ram Power Wagon, I don’t hesitate when it comes to the water and mud. Between TTC’s, G6’s, trail running, and running in the sand, my bearings are starting to squeak their objections. Time for a tear down and clean up.

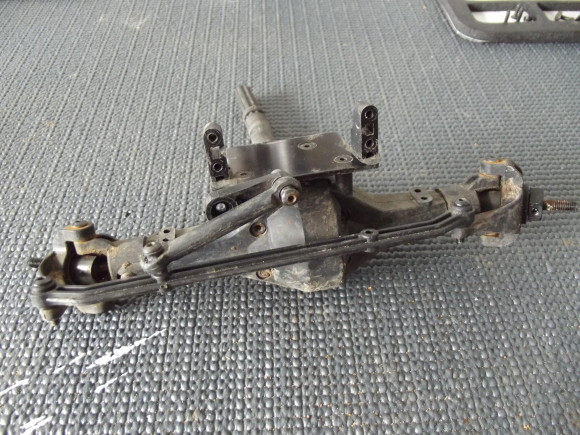

It’s easier to do this kind of job on the Axial SCX10 if you remove the axle from the truck first. Here is the front axle out of the Ram Power Wagon with the servo removed.

We start tearing down by removing the C Hubs and steering knuckles.

We start tearing down by removing the C Hubs and steering knuckles.

We remove the servo mount, and we can split the cases.

We remove the servo mount, and we can split the cases. We’re going to use bearings from FastEddy to replace the stock ones that came with the SCX10. You can get individual bearings from them, or one of these bearing packs. In this package, they include all of the bearings you need for a full vehicle.

We’re going to use bearings from FastEddy to replace the stock ones that came with the SCX10. You can get individual bearings from them, or one of these bearing packs. In this package, they include all of the bearings you need for a full vehicle.

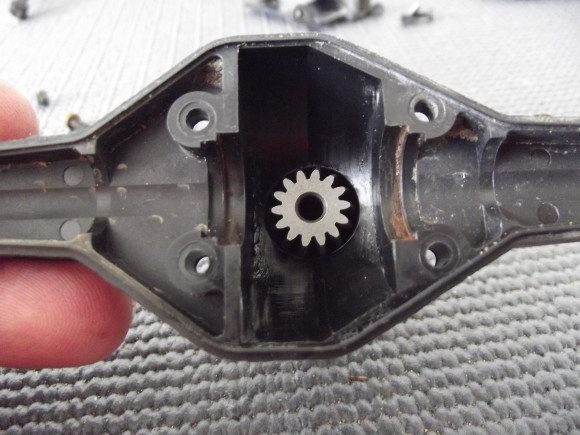

While we have the cases apart, I’m going to put overdrive gears in the front axle. Doing this helps with climbing. It allows the front tires to work harder digging for traction, without the rear tires breaking loose as much.

On the left is the new Input pinion gear, the old one is on the right.

This time the old gear in on the left, the new one is on the right. Interesting to point out, the old gear had little knobs to help hold it in place in the diff housing. The new gear doesn’t have those tabs, so all of the pressure will be on the screws.

Here is the reassembled diff with the new bearings.

The case gets a new bearing where the pinion gear comes out. I used some CowRC Moo-Kleen to clean the gunk out of the case before sliding the new pinion gear into place.

I used some CowRC Moo-Kleen to clean the gunk out of the case before sliding the new pinion gear into place. I slid new bearings on the axle shafts, and slid the axle shafts into the diff.

I slid new bearings on the axle shafts, and slid the axle shafts into the diff. Now we can set it into the case. These gate markers that come in the box when you buy the trucks make nice jack stands.

Now we can set it into the case. These gate markers that come in the box when you buy the trucks make nice jack stands. Here is the jar of CowRC Udder Butter. It is long lasting waterproof grease. We’ll tear the cases apart in a couple months to show how the grease holds up to abuse.

Here is the jar of CowRC Udder Butter. It is long lasting waterproof grease. We’ll tear the cases apart in a couple months to show how the grease holds up to abuse.

I like to really pack the case with grease. Aside from keeping everything lubricated, it also helps stop dirt from getting through.

I like to really pack the case with grease. Aside from keeping everything lubricated, it also helps stop dirt from getting through.  Now we can put the case halves back together.

Now we can put the case halves back together. Four bolts hold it together. The bottom two are nutted, the top two go into the upper link mount.

Four bolts hold it together. The bottom two are nutted, the top two go into the upper link mount.

Now we can put the C Hubs and knuckles back on, they are held with a screw into the axle housing on the top and bottom.

Now we can put the C Hubs and knuckles back on, they are held with a screw into the axle housing on the top and bottom. Here’s the finished product ready to mount to the truck.

Here’s the finished product ready to mount to the truck.

We repeated the same process on the rear. We left the stock gears back there. They make underdrive gears for the rear, which some people opt for. We’ll report back in a few months with another tear down to see how these hold up to the water, mud, sand, and whatever else we throw at them.

We repeated the same process on the rear. We left the stock gears back there. They make underdrive gears for the rear, which some people opt for. We’ll report back in a few months with another tear down to see how these hold up to the water, mud, sand, and whatever else we throw at them.

February 2nd, 2015

February 2nd, 2015  Matt

Matt

Posted in

Posted in  Tags:

Tags: