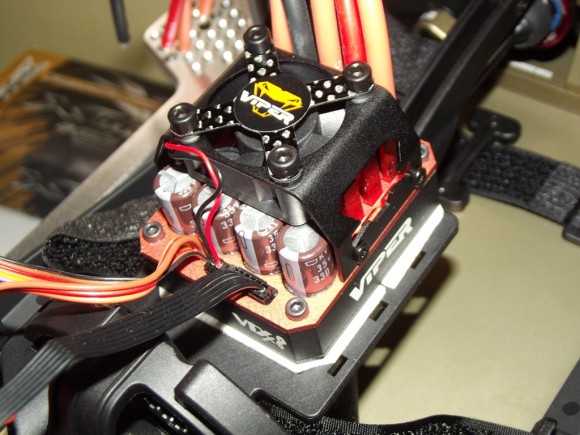

Here is our review of the Viper RC VTX8, 1/8 ESC. I purchased this ESC to run in our Team Durango DEX408. Here’s the build and review of that car.

This is really the story of two ESCs; the one I initially received with the purchase, and the one I received back after sending that one in for repair. Read below for the details.

First here’s some detail from Viper’s website about the VTX8.

The new VTX8 extends Viper R/C’s speed control platform to new heights. Able to handle batteries from 2s to 6s, 2 pole and 4 pole motors from 540 up to 1/8 size motors.

Durable full aluminum waterproof construction helps to make the VTX8 strong enough to handle the regiors of large scale vehicles. Including a built in fan with carbon fiber bracing to ensure the VTX8 is ready to get you to the finish line.

VTX8 Features

- True Sensored technology that provides super smooth power and brake

- Heavy duty all aluminum waterproof case (cooling fan is not waterproof)

- 2~6S Li-Po Support

- Ultra high definition paramter setting (0~100% steps)

- Supports 2-pole and 4-pole 540/550/8th scale motors

- Adjustable BEC up to 7V

- PC V-LINK software ready for firmware upgrade and PC interface

- 8 user profile that allows to import and export in PC V-LINK software

- Auto Power Off function for the maximum safety

Type: Sensored Only

Support Voltage: 2S~6S Li-Po

Support Motor Type: 2/4/6-pole

Max BEC Voltage/AMP: 7V/5A – They say 7V, but it’ll actually go up to 8V if you need it to.

Continuous Current: 220A

Dimensions: 46x53x41mm

Weight: 113g (w/o wires)

First up I’ll talk about build quality. This thing is solid. It is a solid aluminum housing, and feels very well built. Compared to other 1/8 ESCs I’ve used, this one definitely appears like it would take more of a beating without an issue. It comes with presoldered wires for the motor and the battery. You have to solder the wires to your motor, and solder on whatever type of battery connector you are going to use in your vehicle.

Its fairly straightforward to install. The only thing that is really different about this ESC than others out there is the V-port. The V-port allows you to plug in either the Pro Gauge or the EZ Link, and also has the power button. It is on a short 2-3 inch lead hanging off the ESC. I mounted mine right to the side of the ESC. We’ll see how the double sided tape I used holds up to the heat. You need to solder whatever battery connector you need onto the wires, and you’ll need to solder the motor wires. The first motor I used already had wires coming out of it, so I had to solder bullets onto it and the ESC.

So its easy to install, but how well does it work?

If you read the DEX408 build, towards the end I referred to a change in motors even before the build article was complete. You see, before I was able to complete the article, I had already run the car up and down the street a few times. There was something wrong. On that initial run, I could get up to half throttle just fine, but anything beyond half throttle would cause the car to stutter violently. It looked like either a bad sensor wire or that the sensor wire had come unplugged. But neither of those were the case. At this point I was running the Tenshock motor you see in the build pictures. I checked the temperature of the motor, batteries, ESC, battery wires, and motor wires after each test run. What I found was that while the motor and ESC were both relatively cool at around 100 degrees, the motor wires and battery wires were closer to 200 degrees.

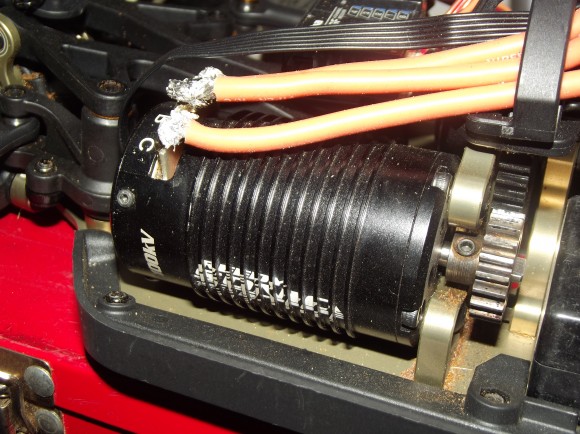

When I had these issues, I reached out to support at Viper RC. They made several recommendations including turning down punch % and turning down forward power, but nothing I tried made it better. The stuttering and shuttering remained, and the motor and battery wires were still getting very hot. Next, Viper recommended I try a different motor. So I picked up a Reedy 2100kv. I took the Tenshock motor out, and sent it up to Kevin in NY. He used the motor in his Team Serpent buggy, and it works flawlessly.

I know, I know. My soldering looked horrible there. But the connections were solid, so I left them there.

Once the Reedy was in, I took the buggy to the track, and put in the first two packs. The Team Durango DEX408 uses 2 batteries wired in series. I run two 2S lipos in series. This ESC goes up to 6S, so you could wire two 3S packs in series. I powered the buggy up, and connected the Viper Pro Gauge to make sure all of the settings were correct. Viper ESCs, using the ProGauge or EZ Link, are definitely on the top of the list of the easiest to adjust ESC settings trackside. The EZ Link is just like a Pro Gauge but without the extra functions not needed for setting an ESC.

I threw in a set of SMC 2S Lipos for the first run. These are 60C, 6500 Mah.

I got about 12 minutes in on that first set of packs. That first run I basically took it easy. I didn’t get past 3/4 throttle, I took the jumps easy. I wanted to make sure everything was ok before I pushed it at all. I knew I was getting close to LVC, so I pulled the car off the track. I temped the motor, ESC, and batteries. The motor was around 130 degrees, the ESC was under 100, and the batteries were right around 90 degrees. The battery wires were warm, but not too hot. The motor wires similarly were warm, but not overly hot.

I took the car back to the pits, and let it sit a few while I watched some of the other cars that were practicing at B & B Hobbies that day. After a couple of minutes, I threw in a second set of full packs, and set out for a second test run.

This time I started to push it. Full throttle down the back straight, taking the bigger jumps, including the big triple in front of the driver’s stand.

About 5 minutes into this second set of batteries, something went wrong. I was entering the infield section of the track, when I heard a stuttering noise come from the buggy, and it came to a sudden stop.

I got the car back to the pits, and pulled off the lid. What I found surprised me. The B wire had come off the motor, and was sitting on top of the A wire. I tried pulling it away, but the solder was stuck together. In the 5 minutes or so between the car shutting down and getting the lid off, the motor wires cooled to a sensible 225 degrees. Yea, you read that right. 225 degrees on the motor wires. The motor was 190, the ESC was 170, the battery wires were 185, and the batteries were 100. Something was certainly wrong.

When I got home, I unsoldered everything from the motor. I cleaned it up the best I could, and resoldered everything. Those that have a Viper ESC know that they make a distinctive set of chimes when they are powering up. This noise is actually coming from the motor as opposed to the ESC. Well, when I tried to power up the ESC, the lights on the V Port acted as they should, but no noise came from the motor.

Again I reached out to Viper, figuring it was time to RMA the ESC. Again they recommended I try a different motor. So in went motor number 3, this time a Tekin 2050 kv.

Why yes, I soldered that lol. I bit the bullet and bought a proper soldering iron. Definitely makes a difference.

I tried powering up the ESC. This time, the lights were acting funky, and the ESC got very hot, very quickly. So I unplugged the battery and contacted Viper. They had me RMA the ESC.

Viper’s Warranty service is second to none. About 15 days later, I had a new ESC in hand. That was fast. The word I got from Viper was there was an internal issue on the one I sent in. Here’s what I know. Apparently I got a very early version of the VTX8 when I first picked it up. The firmware on the new ESC was a different, updated rev. From some of what I’ve read online, there are people out there who have had similar issues to mine, and were also running the older firmware.

So did this new ESC work better than the first? I’m happy to say it did.

I took the buggy to the Intergalactic Electric Championships at CRC Raceway, my old stomping ground.

CRC Raceway is a big, loamy 1/8 sized track. There are plenty of chances to air it out over some big jumps, as well as plenty of opportunities to grab some throttle.

On my initial practice laps, I couldn’t help but notice how smooth the ESC felt. Power delivery was very consistent. Blasts down the long back straight were an exercise of point and hang on! The power from the ESC and Tekin 2050 motor was more than the tires could handle. I turned down punch to try to limit wheelspin. It certainly made a difference. I also noticed after the last round of qualifying on Sunday morning that two of the tires were coming unglued. I got them glued back up right in time for the event to be called on the account of rain.

So how do we rate the VTX8?

| Value |  At the time of this review, the Viper RC VTX8 is $190, or $204 with the EZ Link. This is one of the more expensive ESCs out there, and is in line with the other top of the line manufacturers. I wholeheartedly recommend picking up the EZ Link or a Pro Gauge. It makes settings changes super easy. At the time of this review, the Viper RC VTX8 is $190, or $204 with the EZ Link. This is one of the more expensive ESCs out there, and is in line with the other top of the line manufacturers. I wholeheartedly recommend picking up the EZ Link or a Pro Gauge. It makes settings changes super easy. |

| Build Quality |  The physical construction of this ESC is superb. It is a solid piece, made with obviously high quality material. I scored it like I did due to the issues I had with the initial firmware. I feel like there should have been some additional testing done before they released this ESC. If I had received the newer firmware when I purchased this ESC, this would have been an 8.5. The physical construction of this ESC is superb. It is a solid piece, made with obviously high quality material. I scored it like I did due to the issues I had with the initial firmware. I feel like there should have been some additional testing done before they released this ESC. If I had received the newer firmware when I purchased this ESC, this would have been an 8.5. |

| Performance |  The ESC definitely performs with the newer firmware. Power is readily available, and is butter smooth. It stays cool, and offered plenty of get up and go when I called for it. The ESC definitely performs with the newer firmware. Power is readily available, and is butter smooth. It stays cool, and offered plenty of get up and go when I called for it. |

| Durability |  This review is really the tale of two ESCs. The original ESC I purchased had issues out of the box. I fought with it for over 6 months. I went through 3 motors trying to make it work. I’m giving it an 8 because the new ESC I received, with the new firmware, works flawlessly. This review is really the tale of two ESCs. The original ESC I purchased had issues out of the box. I fought with it for over 6 months. I went through 3 motors trying to make it work. I’m giving it an 8 because the new ESC I received, with the new firmware, works flawlessly. |

| Would I buy again? | I would buy this again, on one condition. I would want to verify what firmware it was running before I purchased it. If it had anything less than the A61 firmware, I wouldn’t touch it. A61 or better, and it seems to be a kick butt ESC for 1/8 scale or 4wd SCT. |

Overall I give the Viper RC VTX8 an 8 out of 10. I would recommend this ESC to anyone looking for a good 1/8 ESC, with this caveat. Make sure you get a unit with the updated firmware. Viper’s customer support is top notch. When I finally made it to the RMA stage, they really took good care of me.

Overall I give the Viper RC VTX8 an 8 out of 10. I would recommend this ESC to anyone looking for a good 1/8 ESC, with this caveat. Make sure you get a unit with the updated firmware. Viper’s customer support is top notch. When I finally made it to the RMA stage, they really took good care of me.

August 31st, 2013

August 31st, 2013  Matt

Matt

Posted in

Posted in  Tags:

Tags: