The journey starts with the center differential.

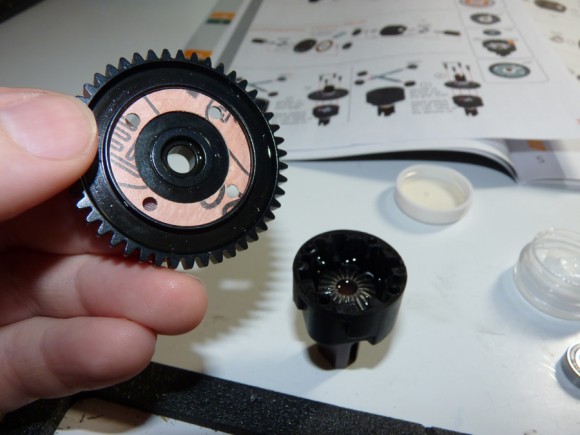

Here is the included 46 tooth sput gear. It is nicely machined and looks to have a great finish on it.

The insides of the diffs have a metal insert in them. These come pressed in already. With the metal on metal contact between this and the output drives, it is vital to lubricate the shafts on the outputs to prevent a cease up due to excessive heat.

So here’s the complete kit unbagged. Fairly straight forward for a diff.

This is the other side of the diff housing.

We’ll start assembly by putting a bearing over the output portion of the housing, lubing the output shaft, and inserting it into the housing.

The output is held in with a pin. An O-ring holds the seal and keeps diff fluid inside. Unfortunately my kit (being first run of the 2.0) shipped with the wrong size O-Rings. Here you can see that they bulged out a bit and did not sit flush in the recess of the diff housing. A quick email to Serpent, and I had new O-Rings in a couple days. This isn’t my first rodeo, so quirks were expected with a newly released model.

Once I had the proper O-Ring fitted, I put in the seal on the spur gear side.

Then the rest of the shaft assembly including bevel gear.

I filled the diff with 15k oil and closed it up. Per Paul Ciccarello‘s setup, I’m running 15/15/10 in my diffs to start.

May 23rd, 2013

May 23rd, 2013  Kevin

Kevin

Posted in

Posted in  Tags:

Tags: