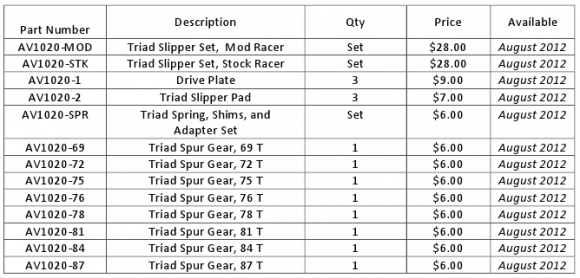

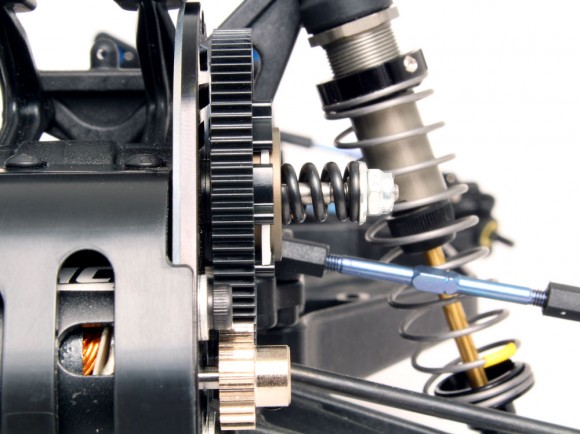

The AVID Triad Slipper Clutch represents the next-generation in slipper clutch design. The Triad slipper utilizes 3 drive plates and 3 slipper pads to make a compact clutch that has better driving feel, lasts longer, and has a lower rotating inertia. A slipper clutch must balance three connected elements: Torque, Pressure, and Friction. AVID has what we believe is a perfect balance in the Triad slipper. The Triad slipper has been tested by World Champions and they agree that this clutch is the future. AVID plans to adapt the Triad design to as many popular models as possible. The first offering in the lineup will be a direct fit to the B4.1, B44.1 and TLR 22 families of cars and trucks.

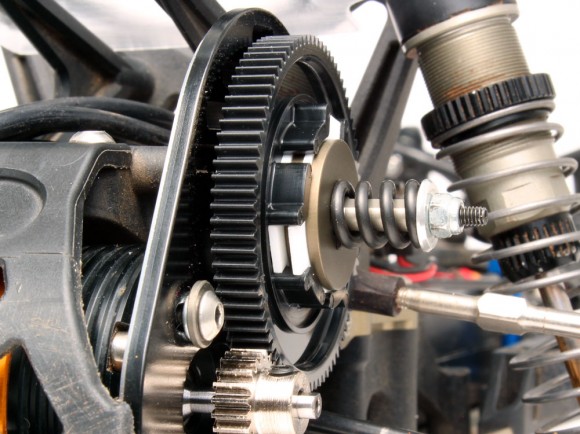

With the advent of brushless and Li-Po technology, 2-plate slipper clutches have been carried over from previous generation cars which were developed for use with brushed motors. The problem is that most 2-plate slipper clutches are pushed to the limit with today’s brushless motors. Therefore, racers have to practically lock their standard 2-plate clutches to handle increased brushless power. The clutch is over-stressed and the power delivery is abrupt with the clutch acting like an on/off switch. Racers are constantly checking their clutch only to find that is has locked up. The Triad Slipper spreads out the stress over 3 drive plates and 4 drive surfaces compared to the current 2 surface-2 plate clutches supplied in most kits. The AVID team created a design which solves all of the problems racers are having with slipper clutches that melt and lock-up. The AVID Triad Slipper will have 20% more torque capacity in a compact package with lower rotating inertia and no lock-ups due to high pressure. On the other side of the coin, large diameter 3-plate clutches have their own set of issues, including excessive rotating weight and excessive torque capacity. Large diameter 3-plate clutches in our testing also have the problem of acting like an on/off switch with abrupt power delivery.

Slipper Features:

- Small diameter, 3 plate compact design

- Proprietary Triad Spur Gears (see below)

- Approximately 20% more torque capacity than a standard slipper clutch

- Progressive power delivery, Designed to avoid lock-up

- 3 identical drive plates for easy assembly and maintenance

- 3 slipper pads which key into the Triad spur gear

- Stock Racer Set for 17.5 racers includes 72 and 76 spur gears

- Mod Racer Set includes 81 and 84 tooth spur gears for a buggy, truck, or short course racer

- Direct fit to the B4.1, B44.1*, and TLR 22 families of cars and trucks. (* 3 standard axle shims req’d, available separately).

- Each set includes 2 spur gears, 3 drive plate, 3 slipper pads, 1 topshaft adapter, 1 spring adapter, 1 spring, and 1 AVID mini decal sheet.

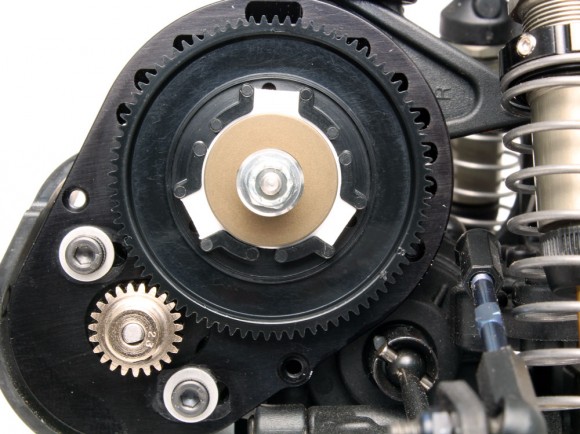

Triad Spur Gear Features:

- Made in the USA from custom blend low-noise material: Most spur gears in the industry are made from material with glass fibers embedded inside to increase strength, but this also increases noise. AVID Triad Spur gears are made out of a premium high-strength plastic material (3 times the impact strength of delrin) with zero glass. The result is a gear that is both strong and quiet.

- Precision 48 pitch tooth form: AVID triad gears roll smoothly because of their involute tooth profile which prevents the teeth from dragging as they roll.

- AVID Triad gears are centerpoint injected for uniform thickness and balance resulting in a true-spinning spur gear. AVID custom tooling ensures the gears won’t wobble!

- Gears are marked with the number of teeth on the outer ring.

- Gears are marked for easy assembly with a “1” for 1 plate, and “2” for 2 plate.

- Available in 69, 72, 75, 76, 78, 81, 84 and 87 tooth configurations.

August 16th, 2012

August 16th, 2012  Kevin

Kevin

Posted in

Posted in  Tags:

Tags: