Rear suspension parts. These are unlike any shocks i’ve ever built before. No oil, no shock caps, and the shafts compress up through the chassis.

HOLY PINION GEAR!! This thing is like an inch long. We also install a large plastic spacer so that the gear mesh lines up.

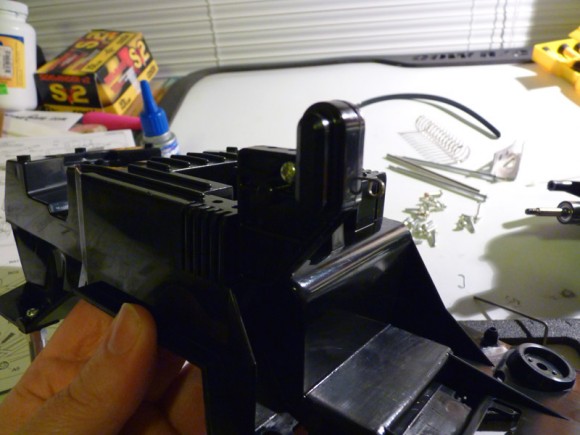

Here’s the motor mounted up to the gearbox.

Another shot of the motor on the gearbox. There’s a dust cover that holds it all together similar to a Clod Buster.

Notice that spacer.

These are the lower rear shock mounts. The grooves slide over splines in the axle tube to prevent them from moving around.

Here are the lower shock mounts attached to the axles.

This is the “axle holder assembly”. The slot in the left holds the axle in place and allows it to move up and down to give it some suspension.

We install a spring onto the assembly to return the axle to a neutral position when the suspension flexes.

Both assembled with springs.

Now we attach them to the chassis tub.

Here you can see how it all works. The front piece on the axle rides in the slot, and the spring rests against them.

Another shot of the axle in the axle holder assembly.

January 23rd, 2012

January 23rd, 2012  Kevin

Kevin

Posted in

Posted in  Tags:

Tags:

[…] Midnight Pumpkin) to run in the 2wd Box Stock class. You can find the full build up on that truck HERE. One of the club’s members sent me a hitch to use on the truck. At the last minute we also […]