I first found this little gem on RC Tech’s For Sale forum. So glad I did too. What we have here is a soldering jig by a small CNC Operation in Georgia called Killer Bee CNC. The jig is CNC milled out of solid aluminum and has 3 clamping areas with thumb screws.

There are 3 main features to the Jig. The first is probably not very useful to us car modelers. It is in the center, and is a series of holes for inserting bullet connectors and holding them upright. I say that they might not be useful for car enthusiasts because they are meant for 5.5mm-8mm bullet plugs. Most of the bullets I use in my everyday R/C’ing are 3.5mm and 4mm. If I could make any improvements to this device, it would be to accommodate those sizes instead of the larger ones for our smaller scale stuff.

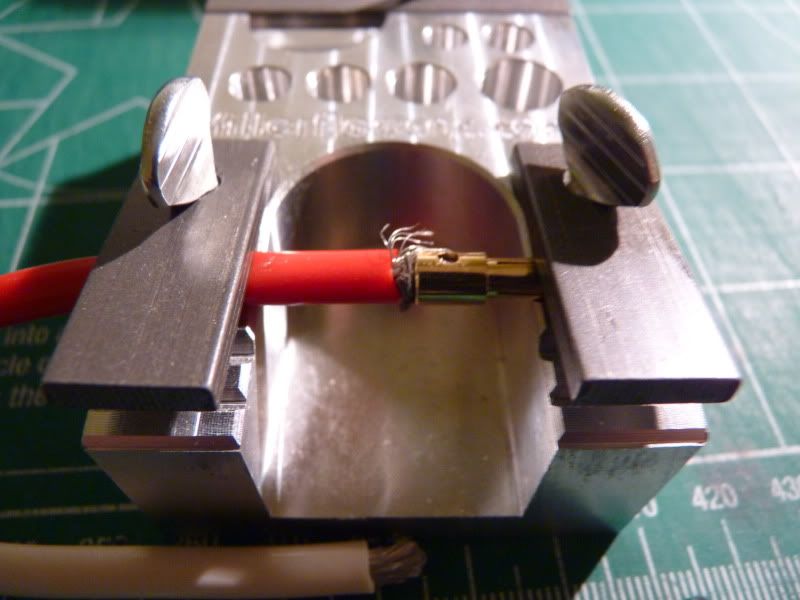

However, all is not lost when it comes to bullet connectors. The next area (with a clamp on each side), has 3 grooves for various gauge wires. This is where those smaller bullet connectors can still be soldered quite easily. Simply clamp the bullet in one side, and feed the wire through the other. Here’s a shot of soldering on a Castle Creations Solid 4mm Bullet Plug onto a Castle 1800kv 1512 1/8 scale motor.

It’s a little awkward at first to figure out (clamps aren’t level with this THICK gauge wire), but it still held it very tight. The thumbscrews work awesome.

The next thing I tried was a Traxxas Male connector on an installed HPI Q-Base ESC. I didn’t feel like removing everything from the car, so I just propped the jig on the mud guard of the chassis and went at it. Worked very well for this too. If you’ve never soldered a Traxxas connecter, they are VERY temperamental. The solder cannot go past a designated area on the gold bar or it will not slide into the connector all the way. Having it clamped down and secured gives you a lot of control over this. Notice the Solder-Catcher too.. it prevents me from having to worry about dripping hot solder on my car in this extreme case of laziness.

The jig makes joining wires a snap too (untested, but same concept as these last two). There’s 3 wire slots for different gauges. If it can accommodate the enormous Castle wires, it should work with any R/C wire you’d need.

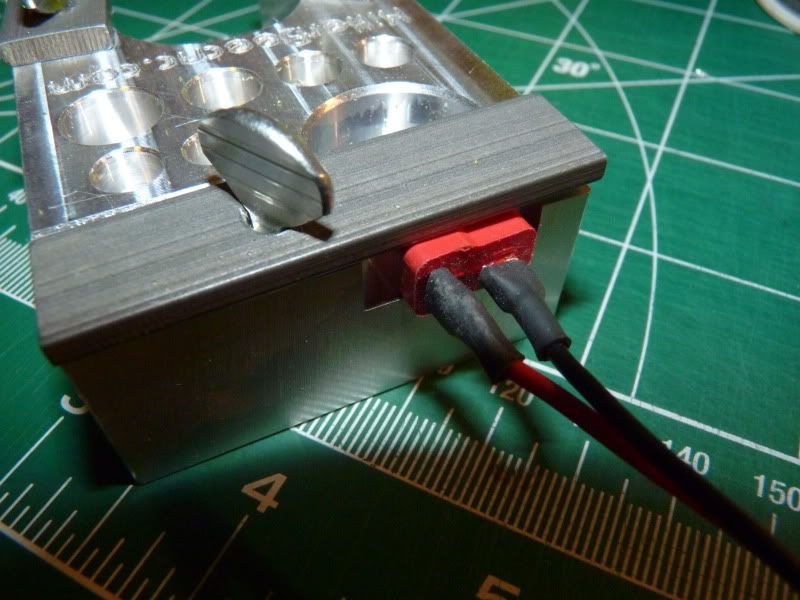

Finally, you have the connector side of the jig. This end was made to make soldering on connectors a breeze. Particularly DEANS style plugs. One of the things I hate most about Deans, is that if you heat up the plug too much, you can melt it a little, and the gold contact bar will shift, causing a mis-fitting plug (will be too tight or not fit at all). This jig makes soldering Deans easy. They claim it also securely holds Multiplex, EC3, Astro, Tamiya, Etc. I don’t use any of these, so they were not included in my testing.

It’s made from high quality Billet T6 aluminum which dissipates heat quickly protecting Deans connectors, prevents heat shrink from premature drawl, and protects other connectors from heat damage as well.

Unit measures 1″H x 2″W x 3″D and weighs 7.5 oz so its stays put! One of my favorite features is that it’s Made in the USA, unlike the clumsy “3rd Hand” that can be found at Harbor Freight or the like. You can tell a lot of work goes into milling these and cleaning up the edges, etc. Not only is it a SOLID piece of aluminum, which cannot be cheap to begin with, but it also works worlds better than the “3rd Hand”. Given the choice, despite the higher price tag.. the Killer Bee CNC jig would be my choice everytime.

Overall it worked great for the things I tried to do with it. No complaints. It’s a great tool if you are into Electric R/C and deserves a spot in your pit box.

4 Stars

(I’d score it higher if the bullet plug holes were more geared towards the R/C gauge sizes, and the price of admission is a little high, but you do get what you pay for)

The Jig is available for $29 (Shipping included) via the killerbeecnc.com or thru R/C Tech.

August 12th, 2011

August 12th, 2011  Kevin

Kevin  Posted in

Posted in  Tags:

Tags:

nice, its one of those things you dont want to buy but wish you did when you need it.